Designed for precision, repeatability, throughput and optimized for Electron Beam Welding.

Tooling systems range from external rotators to internal “rotangles” over multi-station carousels and motions systems. EBES tooling maximizes the number and size of parts that fit into the smallest possible chamber to increase process efficiency.

Internal Rotators

Big Mouth

2 or 3 soft jaw chuck system for rotating long tubular parts, flanges, and rod ends.

Big Mouth with 3 jaw chuck

The Big Mouth comes in various sizes to accommodate a wide range of diameters for tubular components. The through-hole in the chuck is slightly larger than the max. part diameter which allows perfect part positioning underneath the beam even in small spaces.

Rollers to support long and heavy parts are optional as are chamber extensions tubes.

The jaws of the Heavy Duty X24 Big Mouth open from approx. 0.5″ all the way to 4″.

The slim design optimizes chamber space. Convenient and fast part loading and unloading. Parts can be positioned in any angle from 0 to 90 degrees.

Big Mouth X24 with .5″ opening

Big Mouth X24 with 4″ opening

Rotangle

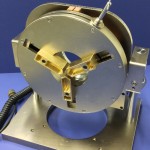

Rotary Manipulator with a tailstock

Rotangle with Tailstock

The Rotary Manipulator is called a “Rotangle” because it rotates a work-piece at various angles between 0 and 90 degrees.

The “Rotangles” are driven by a stepper motor and have a very wide speed range to obtain the required welding speed for small and large diameter parts alike.

There is a 1″ through-hole for perfect part positioning. A double rail tailstock is optional. The work-pieces or work holders are held in collects or 3 jaw chucks.

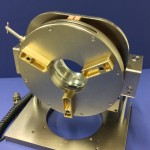

Heavy Duty (HD) Rotangle

HD Rotangle

Heavy Duty (HD) Rotangle with smooth micro stepping drive and optional double rail tailstock

CNC X-Y tables

Available for various vacuum chambers sizes

12 Inch X/Y-Table

The worktable is compact, lightweight, and rigidly constructed to give repeatable results over long periods of time. The standard configuration uses stepper motors for compactness, reliability, wide speed range, and good torque characteristics at low speeds. The table is high vacuum compatible and guards protect the lead screws and wiring from weld spatter.

Carousel

Available with various numbers of spindles

10-Station Carousel in vertical position

The carousels come in various sizes to fit a variety of parts and ultimately to optimize the number of parts that can be welded in one cycle for a given chamber size.

The carousels can be loaded horizontally or vertically and mounted on a slide tray for easy loading and unloading. Each spindle is fitted with precision collets and bearings with a capacity of up to 1/2″ or 1″ for larger chambers.

10-Station Carousel in horizontal position

The optional and detachable tailstock with spring loaded centers slides back and forth to adjust the tailstock spring pressure or to remove parts. Bearings, belts, pulleys, and wiring are concealed for protection from weld splatter.

Stepper motors with micro-stepping drivers are used for spindle rotation and accurate and repeatable indexing. An optional homing position is suitable for automatic “weld-index-weld” operation.

Pneumatic Tailstock

For use on Electron Beam Welders

Pneumatic Tailstock

This tailstock is designed to fit on the side of the vacuum chamber on an electron beam welder opposite a rotator in order to hold parts between centers under pressure. The clamping force is adjustable and permits assemblies to be held together without the need for tack welding and special tooling. The 1″ shaft of the tailstock is fitted with a live center, which can be removed to accommodate any special work holders.

The tailstock is operated via foot switch , which enables the operator to use both hands for loading and unloading parts.